This story begins back in November 2008 when I was visiting a nearby volunteer. He was gathering products from cooperatives around the country to take to the capital for a holiday craft fair for expatriates. One of the product lines to be sold at the craft fair was a group of embroidered greeting cards.

At that time I had just sworn in as a volunteer and had been working with my cooperative for a mere week or two. I had only a rudimentary understanding of the kinds of skills that they had. I saw some examples of embroidery around the workroom of the coop. Mostly this consisted of large table cloths with matching napkins, such as this cross-stitched table cloth seen below.

The embroidery always looked well done, but finishing work seemed to be an issue when they used a sewing machine, such as with the Fesi embroidered pillow case below.

Since large embroidered items such as these take a long time to make and tend to cost more than the average tourist wants to spend, I thought that greeting cards might be a good product for them to pursue.

If the women of the Al-Falah cooperative were going to start making greeting cards it was important that they be in a different style than what was already on the market. Though the embroidery styles of the two groups are totally different, I wanted to take things a step further and have the embroidery directly on the card, instead of having a "window" or somehow pasting some embroidered fabric to the card.

Before I presented this idea to the women I made a prototype to see if it would work. The only cardstock that was available in my town was pink. This was not ideal, but for a prototype it would do. I developed a way to transfer the design onto the card without adding any pencil marks or extra holes. I wanted it to look very clean and have good craftsmanship.

To do this, I drew out my design on graph paper that was the same size as the front of the card. Then, using an empty cardboard box as a work surface, I placed the template over the card and secured it on all corners with straight pins. I used another straight pin to make the additional holes. After I remove the template I'm left with just the holes and I use the original template with the drawing to then embroider the card. I was happy with this system, but very unhappy with the pink cardstock. If the project was going to move forward we would have to find a suitable alternative.

I worked on this project both at home as well as at the cooperative and the women seemed to have minor interest in what I was doing, though they did think it was strange that I was embroidering on paper.

Soon it was springtime. Jon and I heard of an annual event going on in southern Morocco called the Rose Festival. It was late April and work was going very slowly with the cooperative. I needed to get out and do some product research and this was the perfect opportunity.

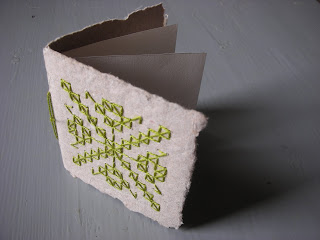

The Rose festival featured several tents with different cooperatives selling their various wares. While browsing around the fair I met a Japanese volunteer (like a Peace Corps volunteer except from Japan). To my delight and surprise, she was also working with her artisans to make embroidered greeting cards!(see photo below) And, she had taught them how to make the paper themselves! Then it struck me. Of course! Handmade paper! This is exactly what we need to be doing!

In college I actually took a whole class on the subject so I had a very good idea about the process, but I earnestly grilled this volunteer to see how she was able to do it here in Morocco. The women that this volunteer worked with were doing a similar style of embroidery that my coop does (a style called "Fesi"), but they were doing it on fabric and pasting it onto the cards, so I still felt like the idea was different enough. Plus, I loved the idea of using materials that were otherwise going to be thrown away. It was the perfect recycling project too! The more I thought about it the more I was convinced that this was the direction we needed to take.

Back in our town, Jon and I spent the next couple of months gathering materials that we would need. The most important thing of course was to make a mold and deckle. Luckily, Jon had taken a paper making course at his school as well, but unlike me, he actually had to make his own mold and deckle for the class and had a better idea of how to construct it. Together we came up with detailed plans.

With this information, we went to one of the many carpenters in town. We didn't need him to actually make it for us- we were planning on doing that ourselves- we just needed him to cut the wood down to very specific measurements. This was very complicated. We wrote all the measurements down in centimeters, knowing that this is of course the standard measurement here. The problem seemed to be with the fact that many of the pieces needed to be cut to a size that wasn't a whole number. Some measurements required the use of 1/2 of a centimeter and some required 1/4 (but nothing smaller or more complicated than that). We stood by and watched him painstakingly measure and mark each piece and cut them. We had the feeling that he wasn't measuring correctly, but didn't want to embarass him in front of his boss. We later found out that every single length of wood (12 in all) were the wrong size. Luckily, all but two were longer than they needed to be, so using a hand saw that belonged to the coop that Jon worked with, he was able to correct these. He also borrowed a drill to screw together all the pieces.

After Jon assembled the mold and deckle I lacquered the whole thing, using several coats and then stapled on two screens; the first one metal with large openings the second one plastic with much smaller holes.

Now that the hard part was over I started to gather the other necessary materials...an extra large tub, a wooden board big enough for two pieces of paper (which also needed to be lacquered), sheets and blankets cut down to the same size as the board, and a blender. Our roof provided the perfect workspace, complete with a conveniently located faucet and drain.

By now it was high summer and the cooperative was on vacation for the entire month of August. This was fine, as I needed time to work out all the bugs in the process. I started making paper myself, trying out different mixtures of materials. At first I was using milk cartons (an idea from the Japanese volunteer), but I soon realized that this wasn't going work very well because before they could be made into paper they had to be separated. To do that they needed to be boiled...it just took too long and too much energy, both my own and that of my buta gas tank. Toilet paper rolls seemed to make the strongest paper and also gave an nice warm color. I also mixed in plenty of egg cartons (free and abundant at every corner store) and Laughing Cow "cheese" boxes. The Laughing Cow boxes need to be soaked first and the labels peeled off, but this is not very difficult.

Now I was making paper! In early September I held a training of trainers for other volunteers who thought they might want to try their hands at making paper with their own cooperatives.

Soon it was Ramadan, and though the women were now back from vacation, their schedule and energy level had completely changed (understandably). At this time I was making as much paper as I could so that I could get it into the hands of the cooperative women and see if they'd even like working with it. For every batch I tried different ratios of pulps and water, trying to get the perfect blend. I made up some new samples (below) and trained them in the technique that I developed. To my relief they absolutely loved embroidering on the cards!

Shortly after my tutorial on how to embroider on the cards, Jon and I took a vacation back to the States for three weeks. By the time we got back it was mid November and getting cold. Since paper making uses so much water (which is very cold to work with when it's cold outside), and winter is a very rainy and wet season (bad for drying paper), training the women how to make the paper themselves was put on hold.

By this time I had lots of paper already made, so they used this to embroider about 30 cards to test market on Peace Corps volunteers and staff during mid service medicals in December.

These first cards were designed so that a flap of paper would fold over the back side of the front, thus hiding any "ugliness" of the "wrong side" of the embroidery. You can kind of see what I mean with the photo of Fatima (below). This was a consequence of the fact that I had not learned the proper way of embroidering Fesi designs. A true Fesi design looks just as good on the back as it does on the front.

Though I gave them a couple of templates to work from to get started (these were based on traditional Fesi designs, but modified slightly), I encouraged them to draw their own designs and use colors that they wanted to use. They took to this right away and came up with some really great stuff. Every couple of days we'd all look at the cards and talk about their craftsmanship. I was careful not to hurt their feelings, but I wanted to be honest with them when I saw something that wasn't up to standard, like if the design was crooked or if the card was all wrinkled. For things like color choices I told them what colors I liked (and possibly tourists as well), but stressed that my opinion on this wasn't the end-all-be-all and that we should see how they sell anyway.

We got so much great feedback from other volunteers and staff in December (see photo below). All but two of their cards sold! This was very encouraging for the ladies and they eagerly wanted to continue with the project and stressed that they'd like to learn how to make the paper themselves, though they understood that they'd have to wait until after the rainy season.

As luck would have it, we had one very sunny, warm, and dry week in January. I knew that this was a fluke and the weather couldn't possibly stay like this for long (and I was right). So I took out all my equipment and worked really hard to make another batch of 24 sheets of paper, this time trying to get really thick sheets.

I used this extra thick and strong paper to make some adjustments to the design. By this time Hafida had taught me how to embroider the proper way and I wanted to showcase the fact that this embroidery does look good from both sides. I also added an insert sheet of "regular" paper (made from recycled paper), which would be better suited for writing. The photos below is my prototype.

Again the women were very receptive to the new design and started embroidering a new batch of cards for the upcoming Marché Maroc Craft Fair in Marrakesh. The quality of each card was better and better and they came up with some really great designs! Below are just some of the 50 cards they made for the fair! (for another image of the cards from the fair see the previous post)

In addition to changing the structure of the card, we also changed the design of the envelope slightly by elongating the closing flap and adding a slit so that the flap would stay closed when inserted.

The women don't have a lot of opportunities to sell their products, especially something like this, which is geared specifically toward a non-Moroccan buyer, so the Marché Maroc Craft Fair in Marrakesh was going to be a very big deal for them. It was important that their products really stood out at the fair. I wanted them to have a really nice display so I started brainstorming some ideas settling, for now, with the display below.

In mid March the weather finally started to clear but as luck would have it, I suddenly developed pneumonia and was unable to work at all for more than two weeks. By the time I got back to work we only had about two weeks left before the Craft Fair (called Marché Maroc) and there wasn't enough time to teach the women paper making because they were busy making their other products. Plus I was in charge of designing all of the marketing materials for the fair which was also very time consuming. So I resigned myself to the fact that it would have to be put on hold yet again.

During the fair I was informed by the organizers of the next upcoming Marché Maroc Craft Fair (in Rabat) that my coop would be able to attend that one as well. This was great news but the craft fair in Rabat was only another two weeks after the one in Marrakesh, which meant that they would again be busy stocking up on other products (mostly crochet).

So, more waiting...

About a week after returning from the craft fair in Rabat I was FINALLY able to teach two women from the cooperative how to make paper! I set the date for Wednesday May 19 and was determined not to push it back any later than that. A couple days before the big day we had a change in the weather and a thunderstorm came through our town, which is very unusual.

Then the day before the workshop I started to see these nasty bugs around outside that look like what we call ear wigs in Ohio. But I didn't think much of it. Then on Wednesday I really started noticing them when I walked to the Artisana where I was meeting the women to lead them back to my house. Hafida was running late and we waited an hour before we could start the workshop. We started inside tearing paper and blending it up then moved to the roof. By this time these bugs where EVERYWHERE! They where landing on us, in the tub of pulp, in the buckets, on the wet paper...I couldn't believe it, of all days! We later heard from several sources that this was very unusual. I guess it was just the right circumstances due to weather. But seriously, it was like a plague of these ugly insects had descended on our town.

But we soldiered on and made some paper anyway. Since it was Fatima and Hafida's first time, and because we where competing with the bugs, we only made about 12 sheets of paper that day. I was very impressed at how quickly they picked up the process, even better than some of the volunteers who I taught back in September. This is really a commendation because with the volunteers there are zero language barriers. Hafida and Fatima acted like they'd been making paper for years! When they did make a mistake they had no problems redoing the process until they got a nice sheet. And besides the bugs and the heat (it was also a scorching hot day), they assured me that they really enjoyed the process!

We haven't done another paper making session since that day. Once the papers were dry I brought them to the Artisana where we ripped and cut them down to make 18 cards and envelopes. They haven't embroidered any of them yet, as they are currently working hard to finish an order (of embroidered t-shirts) for an American company, Mushmina.

This is the end of my paper making tale today, but as you can see we are far from finished. In my estimation, it will take at least a couple more sessions before they will be confident in their abilities and able to pass on their skills to the other members of the cooperative. I really want to see this project continue and be sustainable for them. I want them to completely own it. I want to believe that this project will be an activity that is enjoyable for them as well as one that they can take considerable pride in.

No comments:

Post a Comment